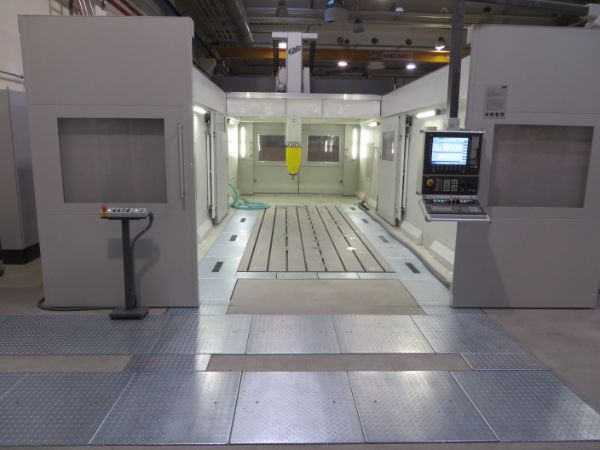

GAMMA L / linear

Machining centre for high-volume components, mainly out of aluminium or ureol.

Sturdy construction, mobile portal at the top, precise machining of material. The well thought-through, fully developed modular system guarantees optimum adaptation to any machining job and any workpiece size. Its range of possible uses extends from 1:1 models used in automobile design, to aircraft parts and boat hulls to railway construction components.