Special solutions / TESLA

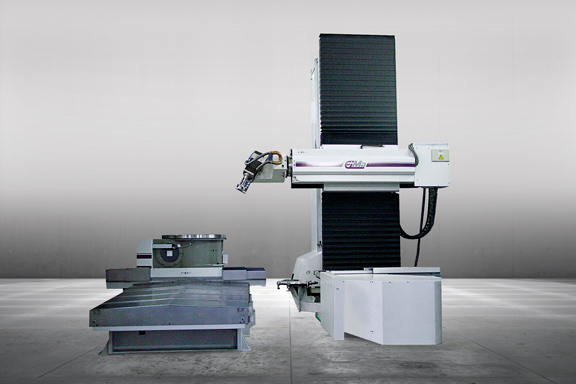

TESLA

This column machine with a movable table and an integrated rotary table impresses particularly with its high accuracy and rigidity.

It enables large components to be machined extremely economically and with great precision. In the example shown here, milling cuts and holes are being made on large CFRP helicopter components.

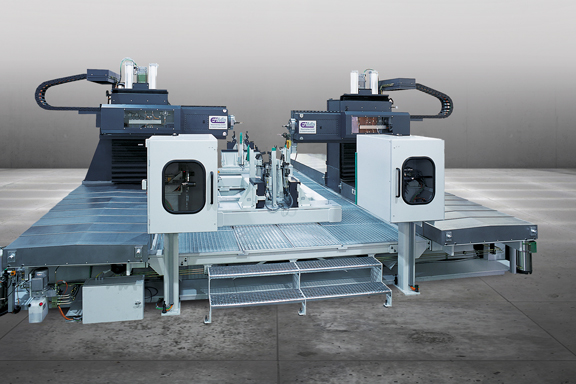

TESLA D

This double-sided column milling machine was developed for vehicle production, specifically for the simultaneous machining of a spaceframe on both sides of the vehicle.

It achieves the shortest cycle times combined with maximum accuracy. The machine can be used both as a stand-alone solution and on a production line. In this case, 3-axis machining operations are performed on aluminium or steel bodies. However, the machine can of course also be fitted with a 5-axis milling head.

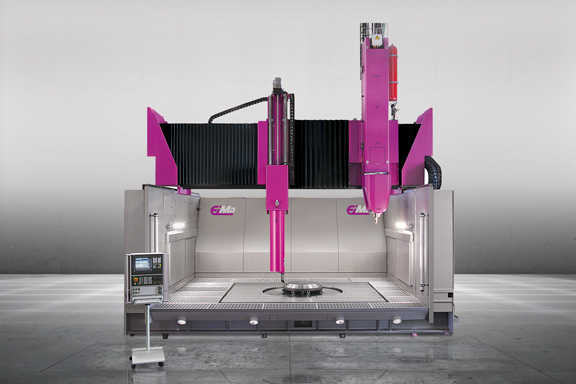

Turning and Milling Centre

Fitting a continuously turning rotary table to a GAMMA machine creates a very interesting variant.

In the example shown here, the table has a diameter of 1,600 mm and a maximum speed of 200 rpm. Depending on the particular application, a Capto tool holder can be installed on the 5-axis milling head or, as in this case, to a separate rotary slide. This allows, for example, a workpiece with an internal hole of Ø 350 mm to be hollowed out 1,300 mm deep.