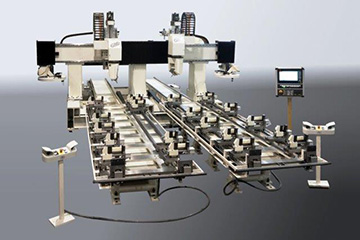

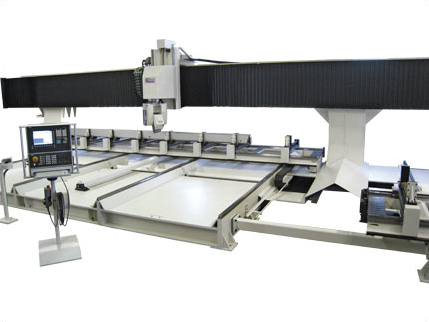

SIGMA

With its double-table design, the SIGMA is second to none in terms of unit costs.

In tandem with a double head (SIGMA DD series), double table machining also eliminates those non-productive times. This is almost like having a second machine. This advantage really makes itself felt in the machining of large, long profiles or nesting parts with long workpiece machining times. Here too, specially developed additional features such as clamping fixtures and handling systems supplement the machine to create individual machining cells.