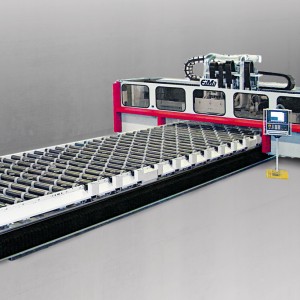

OMEGA

The OMEGA offers the optimum solution wherever there is a need for the precise machining of large-surface components.

It is used very successfully in a wide variety of industries: Vehicle, caravan and waggon construction, prefabricated house building, and also Plexiglas and sheet metal working are just a few examples. Specially developed clamping fixtures, handling systems and the networking of production lines guarantee both competition advantages and an excellent price/performance ratio.