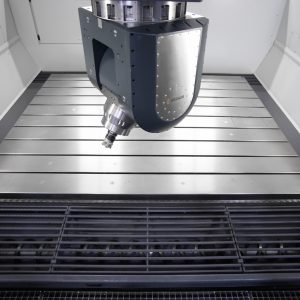

GAMMA XT / linear

This particularly robust series has proven itself superbly in the heavy-duty HSC machining of high-volume steel and aluminium components.

It is used in the mechanical engineering and in the model and mould making. Of course, this machine can also be used for HSC steel machining operations. The modular principle means that the machining centre can be precisely tailored to meet the operator’s individual needs. The mechatronically calculated machine concept guarantees maximum dynamics. You have a choice of motor spindles with HSK-A63 and HSK-A100, and torques of between 120 Nm and 300 Nm.