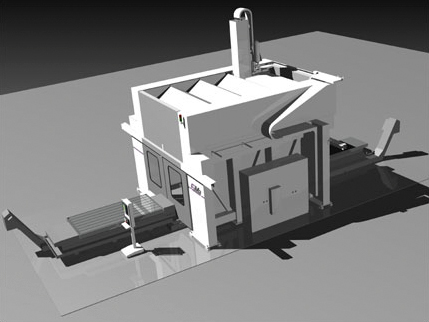

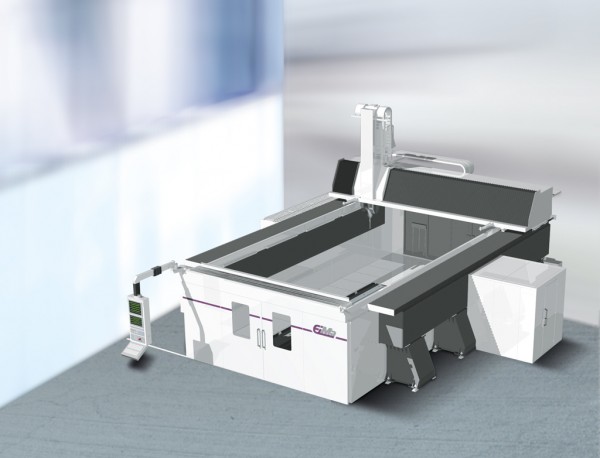

GAMMA XL / linear

The GAMMA XL series was developed for heavy HSC machining of high-volume components made of steel and aluminium.

Its superb properties make it particularly well suited to the exacting demands of mechanical engineering, as well as for model and mould making. In this field too, the perfect modular system guarantees optimum adaptation to any machining job. The linear design in particular brings the user maximum dynamics combined with maximum accuracy thanks to the mechatronically calculated machine concept. You can choose between motor spindles with HSK-A63 and HSK-A100, and torques of between 120 Nm and 300 Nm.