BETA

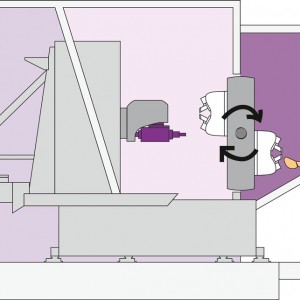

The series BETA developed for the series production of CFRP parts offers the decisive advantages thanks to its rotary table concept.

Setting-up parallel to the machining operation guarantees high production performance, the separate loading and machining area makes an excellent safety and ergonomic concept possible. The chip management reduces cleaning times of workpiece and machine to a minimum. The optimized machining area reduces cost-intensive extraction performances.

The use of individual clamping fixtures as well as the equipment with one or two milling units round off the machine concept for machining of plastics, composites as well as aluminium.