History

2020

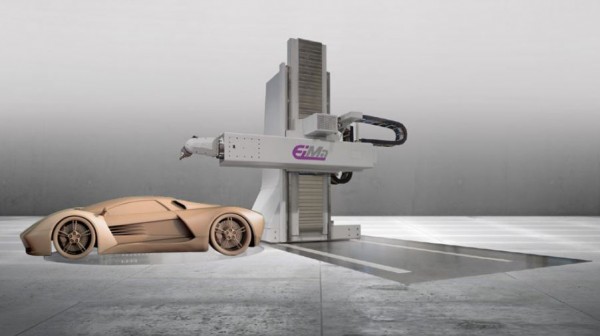

Fastmove: Joint project carbon top-speed 5-axis system for machining tasks of the future

2019

The 3rd generation, Mr. Lukas Eisold, joins the company

2018

Flexible Machining Centre for the manufacture of railway carriages in Russia

2017

Large plant for modelling to Scandinavia

2016

First large machine for the Chinese aircraft industry

2015

EiMa celebrates the company’s 30th anniversary

2014

Newly developed Horizontal Machining Centre BETA successful in the market of processing of CFRP

2013

First presentation of the Portal Milling Machine GAMMA XT at the Hanover Trade Fair EMO

2012

EiMa celebrates the company’s 25th anniversary

2011

EiMa develops new machine component out of CFRP

2010

Successful completion of the joint project SIBUform

2009

Extension of the sales activities in Eastern Europe with new cooperation partners

2008

Foundation of the new production company EiMa Fertigungs-GmbH

2007

Several large projects for the domestic market and European countries are being handled by almost 70 employees at the head office. The company is working on diverse research projects of German universities.

2006

The first high portal machine with moving table and rotary table is delivered to Poland for machining of large parts with a length up to 7,000 mm and a diameter up to 2,300 mm. Further machine deliveries to the Russian Federation.

Certification according to DIN EN ISO 9001:2000.

2005

Extensions of the company in order to meet the requirements regarding machine sizes and order volumes.

Delivery of a further machine to AUDI for the production of the series TT and R8. First delivery of machines to the Russian Federation.

Expansion of the sales network covering machines for machining of metals in Baden-Württemberg with Messrs. Fischer Präzisionswerkzeug-Maschinen, Sindelfingen.

2004

Participation in the specialized exhibition Metalloobrabotka in Moscow.

Large order covering 2 milling machines for machining of aluminium and titanium in the field of aerospace industry, France.

Helmut Gras is appointed Commercial Director.

2003

Foundation of EiMa France for extending the sales activities in France.

Beginning of the cooperation with MAN Ferrostaal AG as cooperation partner for the Russian Federation.

2002

First orders from the aviation industry for machining of composites (EUROCOPTER).

First delivery of a machining centre for fully automatic machining of aluminium (VW).

2001

Machining centres for spaceframes with integrated turnover station (AUDI A8, BMW/Rolls Royce).

2000

Production of the first high portal model making machine (Adam Opel).

Continuous increase of orders covering machines for machining aluminium, in particular for the automotive suppliers.

1999

Production of the first machine with linear drives.

With the two sons Markus and Holger Eisold the second generation of the family enters into the management.

1998

Foundation of EiMa Mitte GmbH as independent sales company, Managing Director Oskar Brückner. Large order from Krupp-Drauz for machining of assemblies and spaceframes.

First orders for machining of aluminium single parts for the automobile industry.

1997

Delivery of two machining centres to FERRARI, Italy for machining of assemblies and spaceframes.

1995

Development of a device for dividing large profile plates. Here for the first time several plates were placed one on top of the other without clamping (patented).

1994

Order from Mercedes-Benz covering three machines with six spindles each. Foundation of EiMa Nord GmbH, as independent sales company, Managing Director Friedrich Klocke.

1993

For prefabricated house building (Schwörer-Haus, Exnorm) special machines for automatic production of components are developed and manufactured.

1992

The first light metal machining centres for doors, windows and car profiles are delivered.

1991

The first CNC machine with three spindles and 68,000 rpm is being built.

1986

Moving from Beuren to the new production site in Frickenhausen.

1984

Foundation of the sole proprietorship Fritz Eisold Geräte und Maschinenbau and acquisition of a company specialised in double crosscut saws.

1983

Fritz Eisold sets up his own business as design engineer.

The company’s founder

In the 1970s the company’s founder, Fritz Eisold, worked as chief design engineer in a company developing and producing tools for the wood, plastic and aluminium industry.

In the 1970s the company’s founder, Fritz Eisold, worked as chief design engineer in a company developing and producing tools for the wood, plastic and aluminium industry.

As a person at that time already being in search of a better solution he realized that due to the potential of the machine technique at that time the efficiency of the high performance tools was limited. Real progress in the machining technique could only be achieved by more rapid and more precise machines.

In 1983 Fritz Eisold set up his own business and in 1984 he acquired a company with high market reputation as manufacturer of high quality double crosscut saws. Then by the introduction of the component construction the basis was laid for a future-oriented design principle which also proved successful again and again for subsequent developments.

His wife Traude assisted and supported him actively – she was in charge of the complete payroll and financial accounting, the shipment of goods and so on – thus enabled Fritz Eisold to concentrate on the further development of the technology and the company.

When in the early 1980s the automatised production in the wood and furniture industry became more and more popular, the demand for CNC controlled production machines grew rapidly. Fritz Eisold realized this at an early stage. Thanks to the experience he had gained from the tool technology and his know-how from machine design he succeeded in working out a sensational solution: EiMa’s first special CNC router in this field. It was a sweeping success and in order to cope with the flood of orders, the company had to be expanded. A new building in Frickenhausen was erected.

Of course, the ideas developed by Fritz Eisold could also be transferred to other fields of activity. Special purpose machines for the production for well-known ski manufacturers, sensational tool change and drive systems and the first portal machines were developed and manufactured.

More and more renowned wood and metal processing companies showed interest in EiMa. They soon realized the potential EiMa machines and equipment offered them for quality improvement and rationalisation.

The company grew continuously and developed into an efficient and highly competent partner for individual solutions.